Image with text

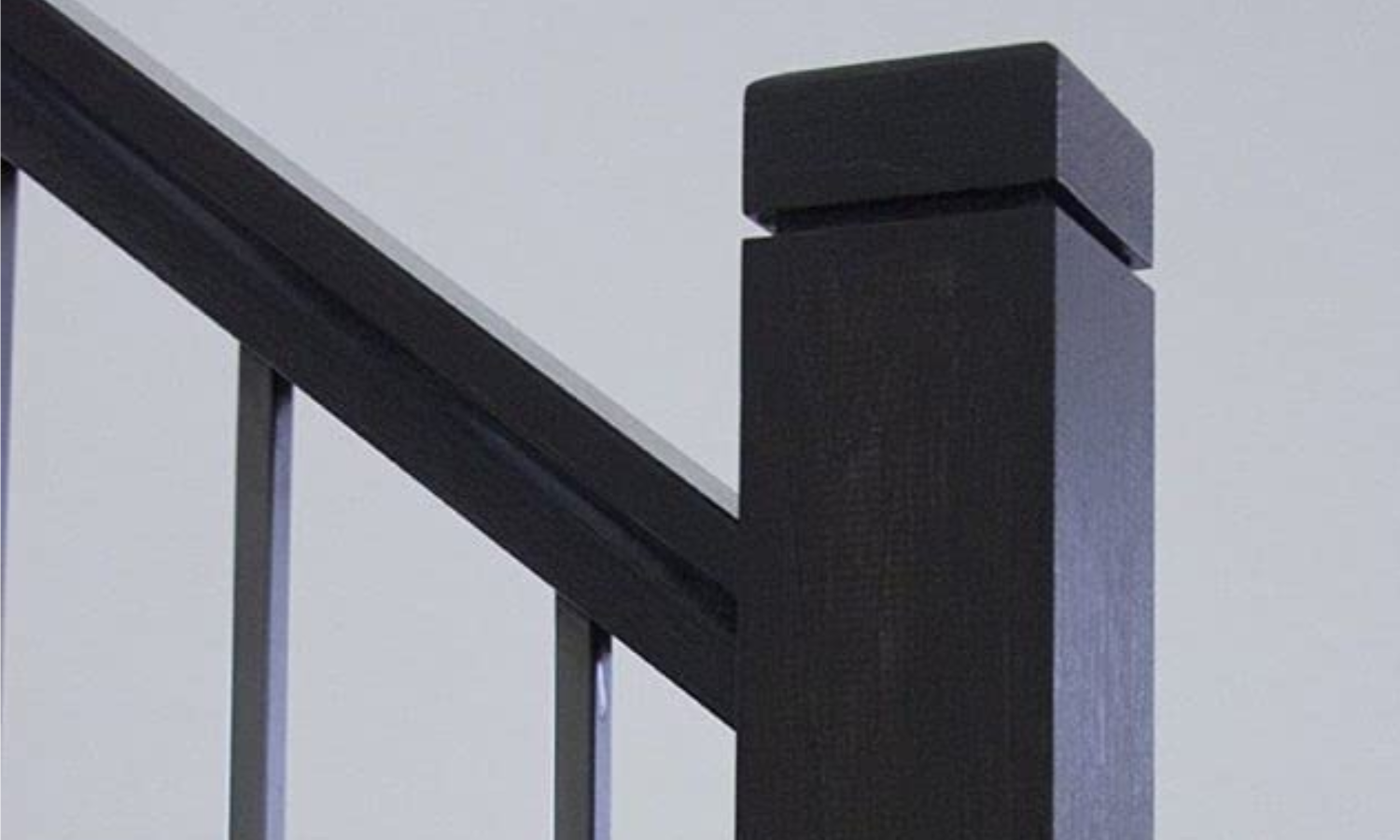

Pair large text with an image to tell a story, explain a detail about your product, or describe a new promotion.

Example title

Use this section to explain a set of product features, to link to a series of pages, or to answer common questions about your products.

Example title

Use this section to explain a set of product features, to link to a series of pages, or to answer common questions about your products.

Example title

Use this section to explain a set of product features, to link to a series of pages, or to answer common questions about your products.

Contact us

Testimonials

★★★★★Author's nameAdd customer reviews and testimonials to showcase your store’s happy customers.

Los Angeles, CA

★★★★★Author's nameAdd customer reviews and testimonials to showcase your store’s happy customers.

Los Angeles, CA

★★★★★Author's nameAdd customer reviews and testimonials to showcase your store’s happy customers.

Los Angeles, CA

★★★★★Author's nameAdd customer reviews and testimonials to showcase your store’s happy customers.

Los Angeles, CA

★★★★★Author's nameAdd customer reviews and testimonials to showcase your store’s happy customers.

Los Angeles, CA